GEOSYNTHETICS STRENGTHEN FOUNDATIONS FOR MARLBOROUGH WINERY EXPANSION

PROJECT DESCRIPTION

The wine industry in Marlborough had been steadily developing since 1967, with most well-known processors already well established in the area. As prime locations for wineries were already occupied, new processing plants were increasingly being built on marginal land.

The Riverlands industrial site posed a significant challenge, being prone to liquefaction and situated adjacent to marshlands. The project required a robust foundation capable of supporting the winery building and large storage tanks while minimising the risk of differential settlement and liquefaction, particularly during an earthquake. The design needed to accommodate tanks of 260,000 and 500,000 litres, each over 8 metres in diameter. Following the lessons learned from the Christchurch earthquake, geotextiles and geogrids had become an established method for reinforcing both private and commercial foundations.

OUR SOLUTION

Geofabrics provided design support to assess the forces and conditions specific to the site. The solution involved using Bidim Green non-woven geotextile combined with triaxial geogrid, which allowed the building to be raised on a reinforced platform and minimised differential settlement.

The design incorporated Bidim Green geotextile as a separation layer, followed by three layers of triaxial geogrid to create a reinforced gravel raft that supported both the winery building and the processing tanks. This approach significantly reduced the need for excavation, lowering transport requirements and associated costs. The combined use of Bidim Green and triaxial geogrid also resulted in substantial savings in aggregates, reducing material usage by approximately 33 to 50 percent.

The solution provided a cost-effective, efficient, and structurally sound foundation suitable for the challenging site conditions, ensuring long-term stability for the Riverlands winery facility.

PRODUCT USED

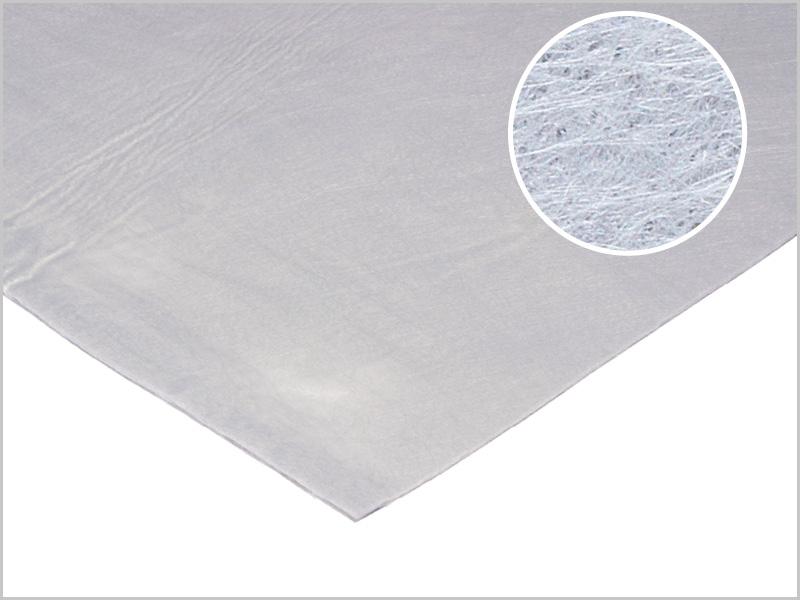

Bidim® Green Non-Woven Geotextile

- A strong three-dimensional structure with high elongation and equal biaxial strength properties in both directions

- Made with a combination of recycled PET and virgin plastic materials

- Provides excellent filtration, separation, drainage and protection performance

- Reduced need for quarried fill materials and reduced construction times

SIMILAR PRODUCT

- A multi-axial geogrid made from punched polypropylene sheets, forming a unique hexagonal structure with triangular apertures that confine and interlock with aggregate for soil stabilisation and ground improvement

- Reduces aggregate layer thickness by up to 50% without compromising performance, lowering excavation and fill costs

- Enhances layer stiffness to allow the use of lower-quality or recycled fill materials, reducing material costs

- Speeds up installation, offering a fast, cost-effective stabilisation solution for roads, working platforms and heavy-vehicle pavements

DISCLAIMER - The images depicted in the photographs on this page are similar to the Geofabrics' products listed but they are not the same.